STP 和 RSTP 在工業自動化中的作用:確保網路可靠性

分享

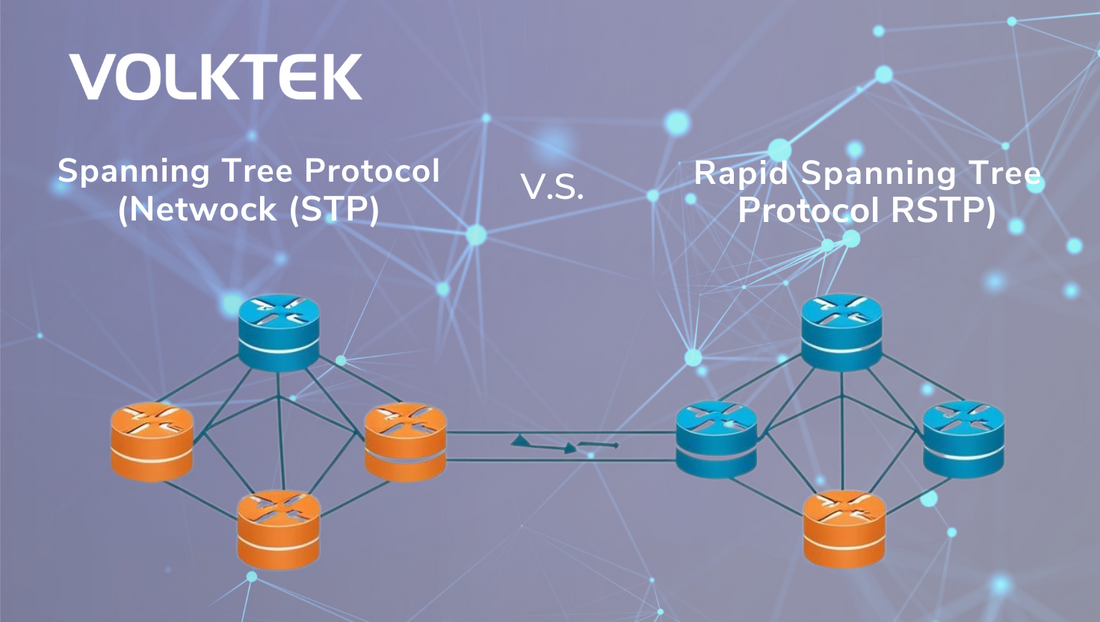

在快速發展的工業自動化領域,機器和系統之間的無縫通訊至關重要。隨著工業網路變得越來越複雜,確保網路穩定性和冗餘對於防止代價高昂的停機至關重要。這就是生成樹協定 (STP) 和快速生成樹協定 (RSTP)發揮關鍵作用的地方。

什麼是 STP?

生成樹協定 (STP)是一種旨在防止乙太網路中出現環路的網路協定。在多個交換器互連的工業自動化中,冗餘路徑對於可靠性至關重要。然而,這些冗餘鏈路可能會形成網路環路,從而導致廣播風暴和網路故障。 STP 偵測並阻止冗餘路徑,只允許一條活動路徑,同時保持備援連結隨時準備進行故障轉移。

STP 在工業自動化的局限性

雖然 STP 可以有效地防止網路環路,但其收斂時間較慢(30-50 秒) ,這可能導致工業流程暫時中斷。在製造業和智慧電網等即時通訊至關重要的行業中,這種延遲是不可接受的。

什麼是 RSTP?

快速生成樹協定(RSTP)是STP的進階版本,可以顯著提高收斂速度。 RSTP 不需要花費一分鐘的時間來重新配置網路拓撲,而是可以在幾秒鐘內完成。這確保了工業自動化網路能夠快速從故障中恢復,並保持平穩運作。

RSTP 在工業自動化的優勢

- 更快的恢復: RSTP 透過在故障後快速重新建立網路路徑來減少停機時間。

- 增強冗餘:透過更快的故障轉移機制,RSTP 可確保啟動備援路徑而不會中斷關鍵程序。

- 提高可擴展性:工業網路不斷擴展,RSTP 能夠以更高的效率支援更大的網路。

- 即時應用的更好性能:汽車製造、石油和天然氣以及發電廠等行業依賴低延遲網絡,這使得 RSTP 成為比傳統 STP 更好的選擇。

為什麼 STP 和 RSTP 對工業自動化至關重要

工業網路必須具有彈性、安全性並且能夠處理關鍵任務操作。 STP 和 RSTP的實施提供了:

- 網路穩定性:防止環路並最大限度地減少中斷。

- 增加正常運作時間:減少停機時間,確保無縫自動化。

- 增強安全性:避免導致設備損壞或安全隱患的網路故障。

- 節省成本:避免昂貴的停機

隨著工業自動化隨著工業 4.0不斷推進,可靠的網路基礎設施成為重中之重。雖然STP在某些工業設置中仍然有用,但 RSTP因其快速收斂和提高的效率而成為首選。希望建立強大自動化網路的公司應優先考慮支援 RSTP 的工業交換機,以增強其運作可靠性。

透過實施 STP 或 RSTP,企業可以確保高可用性、防止網路故障並優化工業自動化效能