為什麼工業 PoE 交換器對於機器控制至關重要?

分享

介紹

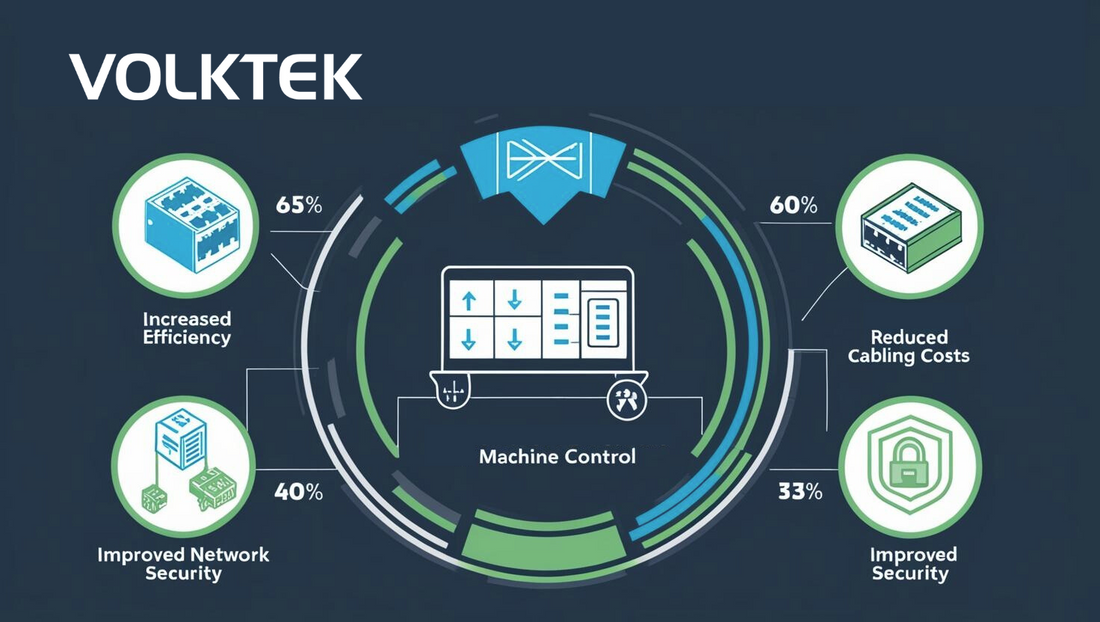

在現代工業自動化中,工業 PoE(乙太網路供電)交換器已成為機器控制系統的重要組成部分。這些專用交換器不僅提供可靠的乙太網路連接,還為IP 攝影機、感測器、控制器和執行器等關鍵自動化設備供電。在本文中,我們將探討工業 PoE 交換器在機器控制中的重要性以及它們如何提高營運效率、網路穩定性和工業自動化性能。

什麼是工業 PoE 交換器?

工業 PoE 交換器是一種專為惡劣的工業環境設計的堅固的網路交換器。與標準商用交換器不同,工業級交換器提供:

工作溫度範圍廣(-40°C 至 75°C)

具有強大的抗衝擊、抗振動和抗 EMI(電磁幹擾)能力

冗餘電源輸入,提供故障轉移保護

用於網頁優化的託管和非託管選項

PoE+ 和 PoE++ 支援為高功耗設備供電

工業 PoE 交換器在機器控制的關鍵優勢

1.簡化電源和資料傳輸

PoE 交換器在機器控制方面的最大優勢之一是它們透過單一乙太網路電纜同時傳輸電力和資料。這樣就無需額外的電源和接線,從而降低了安裝的複雜性和成本。

2.在惡劣環境下可靠運行

工業自動化環境使網路設備暴露在極端溫度、灰塵、濕度和電氣幹擾下。工業 PoE 交換器採用無風扇設計、堅固的金屬外殼和工業級組件,確保即使在惡劣條件下也能不間斷地運作。

3.增強網路冗餘,最大限度減少停機時間

機器控制系統需要較高的網路正常運作時間。工業 PoE 交換器支援:

具有乙太網路冗餘協定(RSTP、ERPS、MRP)的環形拓撲

冗餘電源輸入,防止故障

毫秒級的故障轉移恢復這些功能可防止停機並確保機器的持續運作。

4.無縫即時通信

機器控制依賴於即時乙太網路協議,例如EtherNet/IP、PROFINET、EtherCAT 和 Modbus TCP 。工業 PoE 交換器提供低延遲、高頻寬通信,確保控制器、機器人和其他自動化系統之間的精確同步。

5.支援高功率 PoE 設備

許多自動化系統使用高功率設備,包括:

用於機器視覺的 PoE 供電 IP 攝影機

實現無縫工廠通訊的無線接入點 (AP)

用於即時監控的 PoE 感測器工業PoE+(30W)和 PoE++(60W、90W)交換器無需額外的電源即可為這些設備供電。

6.遠端監控和管理

管理型工業 PoE 交換器提供:

SNMP(簡單網路管理協定)用於網路診斷

基於 Web 的使用者介面,可輕鬆配置

PoE 調度以優化功耗這些功能允許遠端故障排除和監控,從而提高系統效率。

工業 PoE 交換器在機器控制中的用例

1.工業機器人與自動化

PoE交換器為機械手臂、CNC工具機和自動組裝線提供可靠的連接,確保順利運作。

2.機器視覺系統

PoE 供電的IP 攝影機和基於 AI 的影像處理器可協助製造商即時檢查產品並偵測缺陷。

3.工廠物聯網網絡

工業 PoE 交換器透過將感測器、執行器和閘道連接到集中控制系統,實現IIoT(工業物聯網)應用。

4. SCADA 和遠端監控

PoE 交換器為PLC 和 SCADA 設備供電,實現對機器和流程的即時監控和控制。

選擇合適的工業 PoE 交換機

選擇用於機器控制的工業 PoE 交換器時,請考慮:

PoE 連接埠數量(8、16、24 個連接埠等)

PoE 功率預算(PoE、PoE+ 或 PoE++)

託管與非託管(託管交換器允許進階配置和監控)

冗餘和故障轉移支持

乙太網路速度(千兆、10GbE)

結論

工業 PoE 交換器在機器控制系統中發揮至關重要的作用,提供電力、網路穩定性和即時通訊。透過在工業自動化中整合PoE 交換機,製造商可以提高效率、可靠性和可擴展性,同時降低佈線複雜性。隨著自動化的不斷發展,部署正確的工業 PoE 交換器對於在智慧工廠和工業物聯網環境中實現最佳效能至關重要。